Hotline

+86-15286985260

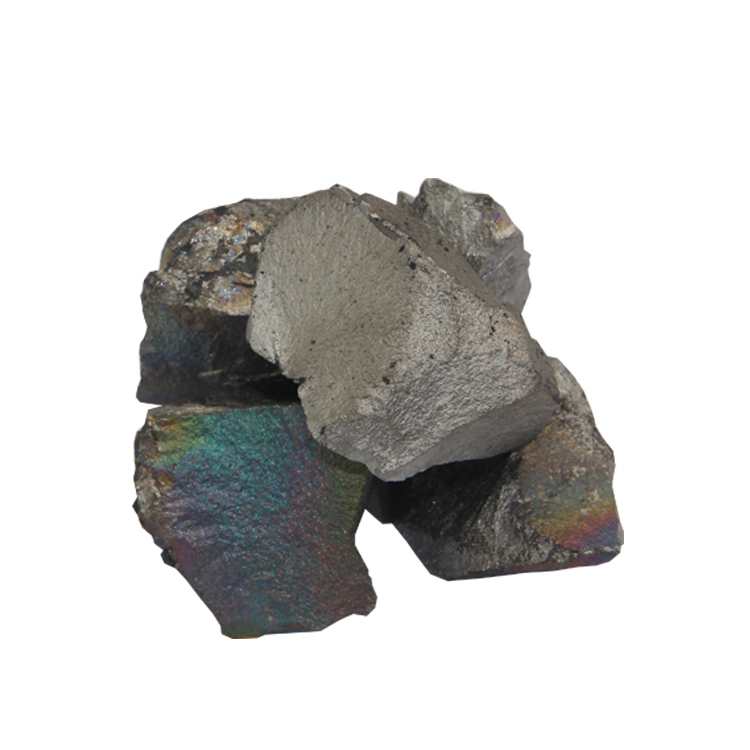

Ferro Manganese is an alloy of manganese and iron, which also contains a small amount of other elements such as carbon, silicon, and phosphorus. The main grades of ferromanganese are classified according to the carbon content of the alloy. According to their carbon content, they are high carbon ferromanganese, medium carbon ferromanganese, low carbon ferromanganese, and micro carbon ferromanganese. Ferromanganese alloys that contain sufficient amounts of silicon are called silicon manganese alloys.

Ferromanganese is made from manganese ore. Made by melting in a blast furnace or electric furnace. Ferromanganese is also a commonly used deoxidizer in steel, and manganese also plays a role in desulfurization and reducing the harmful effects of sulfur. Therefore, almost all kinds of steel and cast iron contain a certain amount of manganese. Ferromanganese is also used as an important alloying agent. Widely used in structural steel, tool steel, stainless and heat resistant steel, wear-resistant steel, and other alloy steels.

Ferromanganese is divided into low carbon ferromanganese, medium carbon ferromanganese, and high carbon ferromanganese based on its carbon content.

Low-carbon ferromanganese is a type of ferromanganese product with low carbon content. Low-carbon ferromanganese is mainly used in steelmaking to improve the hardness and toughness of steel and effectively remove oxygen during steelmaking. Low-carbon ferromanganese is a necessary raw material for smelting many special steels.

"The characteristic of medium carbon ferromanganese is its low carbon content. Medium carbon ferromanganese can be used in various fields, but it is still widely used in the field of steelmaking. Manganese is a good element for steelmaking. Medium carbon ferromanganese can greatly improve the hardness value of steel in steelmaking, and is used to produce special steels such as special steels and stainless steels."

High carbon ferromanganese contains a small amount of trace elements, mainly manganese and iron, accounting for about 92% of the elements. The carbon content is also a relatively high type of ferromanganese. High carbon ferromanganese in electric furnaces is mainly used as a deoxidizer, desulfurizer, and alloy additive in casting. High carbon ferromanganese is mainly added during casting.

Mn | C | Si | P | S | 10-50mm | |

Low Carbon Ferro Manganese | 80 | 0.4 | 2.0 | 0.15/0.3 | 0.02 | |

80 | 0.7 | 2.0 | 0.2/0.3 | 0.02 | ||

Medium Carbon Ferro Manganese | 78 | 1.5/2.0 | 2.0 | 0.2/0.35 | 0.03 | |

75 | 2.0 | 2.0 | 0.2/0.35 | 0.03 | ||

High Carbon Ferro Manganese | 75 | 7.0 | 2.0 | 0.2/0.3 | 0.03 | |

65 | 7.0 | 2.0 | 0.2/0.3 | 0.03 |

The company has strong financial strength, complete production processes and equipment, and a complete quality assurance system. The product quality is stable and reliable, and it is mainly sold to Japan, South Korea, Taiwan, Vietnam, South America, Europe, and other countries and regions to maintain long-term cooperative relations.