Hotline

+86-15286985260

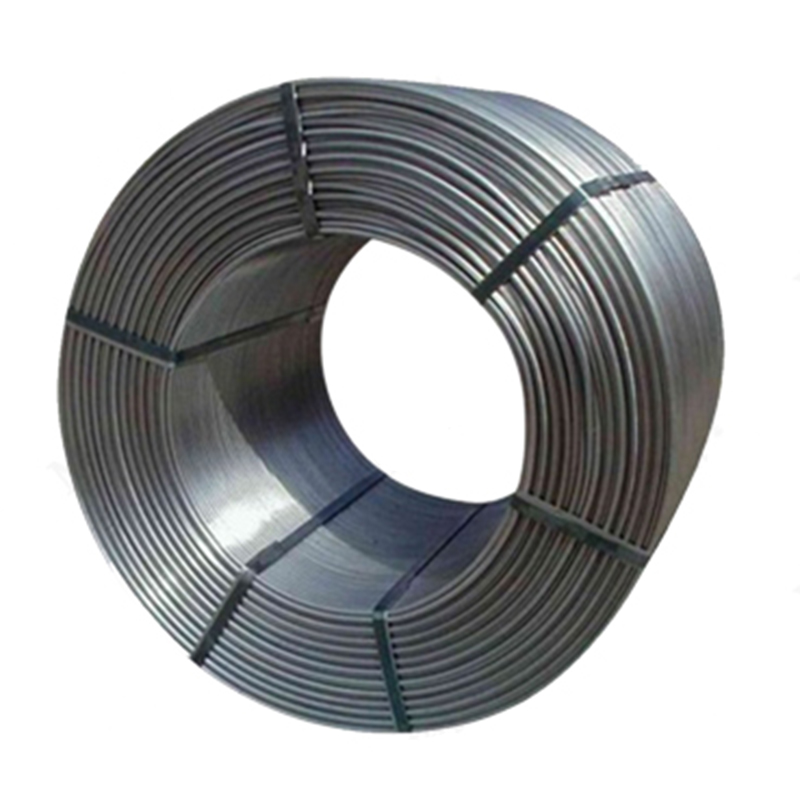

The cored wire is used to break various additives (deoxidizer, desulfurizer, modifier, alloy, etc.) that are to be added to molten steel or iron into a certain particle size, and then include them into a composite material with any length using a cold rolled low-carbon steel strip. According to the different alloy powders, they can be divided into: calcium silicide cored wire, calcium silicomanganese wire, calcium silicide barium wire, barium aluminum wire, aluminum calcium wire, calcium iron wire, pure calcium wire, and so on. The winding looks like a coil.

The cored wire technology is a kind of outside furnace refining method developed on the basis of jet metallurgy technology. The cored wire is suitable for steel making and casting. Used in steelmaking can purify the morphology of steel inclusions, improve the castability of molten steel, improve the usability of steel, significantly increase the yield of alloy, reduce alloy consumption, reduce steelmaking costs, and achieve significant economic benefits.

1. It is conducive to adjusting and controlling the content of easily oxidized elements and trace elements, greatly improving the alloy yield, reducing smelting costs, shortening smelting time, and accurately controlling the composition.

2. It plays a role in purifying molten steel and partially changing the properties and morphology of slag inclusions, improving the quality of molten steel and improving the casting state.

3. The cored wire can be divided into two types: internally drawn and externally placed. The mechanical equipment required for wire feeding is simple and reliable, with a small floor area. In particular, the internally drawn cored wire is more suitable for small and narrow areas.

Model | Diameter (mm) | chemical composition | The heavy line (g/m) | Thickness of line (mm) | Alloy weight (g/m) |

Ca | 9.0-9.5 | Ca:97%±1% Al:0.7%max Mg:0.7%max Mn:0.5%max Si:0.5%max Fe:0.5%max | 50-68 | 0.5-0.7 | |

CaSi | 13±0.5 | Ca:28-30% Si:50-60% | 390±10 | 0.4±0.05 | 220±10 |

Carbon | 13±0.5 | C:96%min | 300±10 | 0.4±0.05 | 130±10 |

FeCa | 13±0.5 | Ca:30%min | 430±10 | 0.4±0.05 | 260±10 |

Sulfur | 13±0.5 | S: 99%min | 330±10 | 0.4±0.05 | 160±10 |

The company has strong financial strength, complete production processes and equipment, and a complete quality assurance system. The product quality is stable and reliable, and it is mainly sold to Japan, South Korea, Taiwan, Vietnam, South America, Europe, and other countries and regions to maintain long-term cooperative relations.