Hotline

+86-15286985260

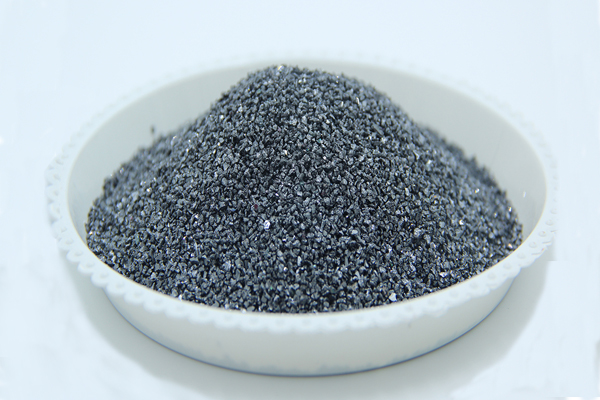

Overview of the application of silicon carbide in the field of casting

Silicon carbide is made of carbon and silicon raw materials heat treatment, with high hardness, high strength, high temperature resistance, corrosion resistance and other characteristics, so it is widely used in the field of casting. Silicon carbide products mainly include containers, stoves, pipes, ceramic accessories, kiln utensils and so on. In addition, silicon carbide can also be used as a coating additive to improve the surface quality of castings.

The advantages of silicon carbide in the field of casting

1. Good high temperature resistance

In the field of casting, it is often necessary to deal with high-temperature materials, such as molten aluminum. Silicon carbide has high temperature resistance and can withstand wear and corrosion at high temperatures. For traditional ceramic products, cracking and deformation are easy to occur at high temperatures, and silicon carbide can avoid these problems.

2. Strong corrosion resistance

Corrosive materials are often encountered in the casting field, such as acidic and alkaline materials. Silicon carbide has corrosion resistance and can be used for the treatment of most corrosive materials.

3. Long life

Compared with traditional ceramic materials, silicon carbide has a longer service life. This is because of the hardness of silicon carbide, good wear resistance, not easy to damage.

4. Cost effective

Although the price of silicon carbide is higher, it still has a cost-effective advantage compared with traditional ceramic materials. This is because silicon carbide has better performance in terms of service life and performance.

Silicon carbide Conclusion

In short, silicon carbide is a widely used material in the field of casting. Because of its unique performance, it can effectively improve the casting quality, improve production efficiency, and has a long service life, so it is widely welcomed by foundry manufacturers.